Chip Firms in Malaysia Confront Uncertain Futures Amid Tariff Concerns

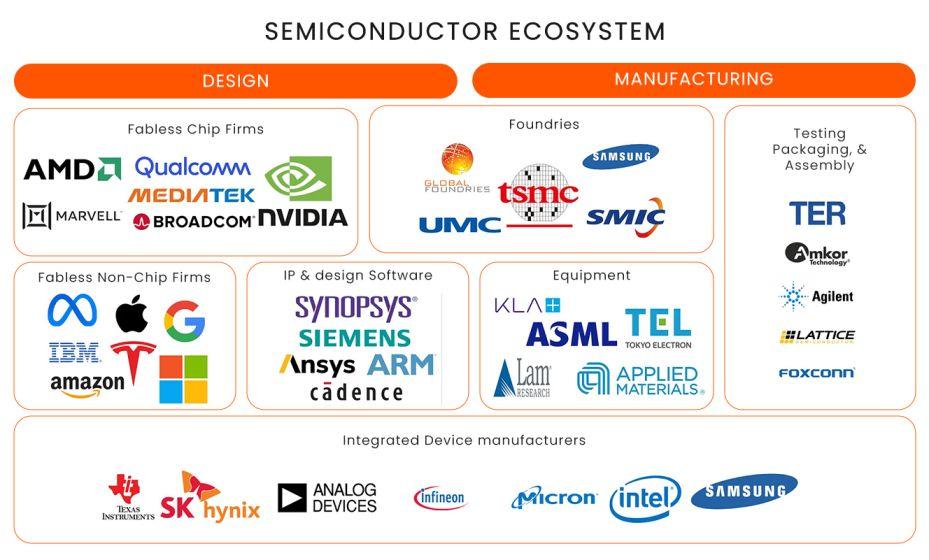

The semiconductor industry in Malaysia, crucial to the global supply chain, finds itself in a precarious position as companies navigate through the murky waters of tariff uncertainties. With escalating trade tensions and shifting regulatory landscapes, chip manufacturers are forced to reassess their investment strategies.Many firms, once poised for expansion, are now adopting a more cautious approach, leading to a notable slowdown in capital expenditures. This reluctance is attributed to fears that potential tariffs could inflate operating costs and disrupt established market dynamics.

Industry experts believe that the ramifications of these tariff concerns are multifaceted. They include:

- Reduced competitiveness: Local firms may struggle to compete with foreign alternatives if tariffs are imposed, diminishing their market position.

- Supply chain disruptions: Companies are re-evaluating their supply chains to mitigate risks, possibly leading to longer lead times and inefficiencies.

- Job stability concerns: With investment plans paused, job creation may stagnate, affecting not only the companies but also the broader economy.

As these uncertainties linger, stakeholders in the Malaysian semiconductor sector remain vigilant, weighing their options while hoping for a resolution that could restore confidence and spur growth in this critical industry.

Economic Ramifications of Tariff Changes on Malaysia’s Semiconductor Industry

The recent uncertainty surrounding tariff changes has cast a shadow over Malaysia’s semiconductor sector, a critical player in the global supply chain. As investors weigh the implications of potential new tariffs,companies are recalibrating their strategies,leading to a noticeable pause in expansion plans. this apprehension is driven by several key factors:

- Increased Production Costs: Companies face higher input costs due to potential tariffs on raw materials, which could erode profit margins and deter investment.

- Market access Challenges: Uncertain tariff rates may limit access to crucial markets,making it difficult for firms to forecast sales and adjust operations accordingly.

- Supply Chain Disruptions: Fluctuating tariffs can disrupt established supply chains, prompting firms to reconsider their manufacturing and logistics strategies.

These dynamics create a ripple effect that can hinder innovation and competitiveness within Malaysia’s semiconductor industry. Firms reliant on steady investment influx now find themselves in a holding pattern, prioritizing financial stability over aggressive growth. The resulting stagnation could jeopardize Malaysia’s position as a pivotal hub in technology manufacturing, particularly as other nations seek to capitalize on their advantages in the semiconductor arena:

- Diminished R&D Funding: With investments on hold, many firms may reduce their research and development expenditures, stalling advancements in technology.

- Talent Retention Issues: As project delays mount, attracting and retaining top talent becomes increasingly challenging, leading to a brain drain in the sector.

- Global Competitiveness at Risk: Prolonged uncertainties may encourage firms to relocate their operations to more stable environments, diminishing Malaysia’s appeal as an investment destination.

Strategies for Resilience: Navigating Investment Challenges in a volatile Market

The recent hesitation among chip manufacturers in Malaysia to advance their investment strategies highlights the growing concern over fluctuating tariffs and regulatory pressures. Amidst escalating tensions in global trade relations, these companies are reevaluating their budgets and growth trajectories. This decision comes as firms weigh the potential financial implications of tariffs, which could disrupt supply chains and alter market competitiveness. to address these uncertainties, companies are adopting a proactive approach by exploring alternative markets and adjusting their product offerings based on current economic climates.

Strategically, firms are focusing on several key areas to bolster their resilience:

- Diversification: Investing in a broader range of technologies and markets to minimize the impact of localized tariff issues.

- Collaboration: Forming strategic partnerships with other industry players to share risks and enhance innovation.

- Cost Management: Streamlining operations to maintain profitability even during slowdowns and unforeseen economic pressures.

- Market Intelligence: Leveraging data analytics to forecast trends and adjust strategies accordingly, ensuring that firms remain agile in response to market changes.

By adopting these measures, chip manufacturers can not only navigate the current landscape of tariff uncertainty but also position themselves for long-term growth, irrespective of external economic pressures.

Policy Recommendations to Foster Growth in Malaysia’s Chip Manufacturing Sector

The recent hesitation among chip manufacturers in Malaysia to commit to new investments, primarily driven by concerns over tariffs and regulatory uncertainties, underscores a pressing need for government intervention. To reinvigorate the sector and alleviate investor apprehensions,a comprehensive policy framework should be developed that addresses both immediate and long-term challenges faced by these companies. Key recommendations for the government include:

- Implementing Clear Tariff Structures: Simplifying and clarifying tariff regulations can help build confidence among chip manufacturers, enabling them to plan investments more strategically.

- incentivizing Research and Development: Establishing tax breaks or grants for R&D initiatives can spur innovation and competitiveness in the chip manufacturing sector.

- Enhancing infrastructure: Investing in infrastructure improvements, such as expanding semiconductor fabrication facilities and ensuring reliable electricity supply, can bolster the attractiveness of Malaysia as a manufacturing hub.

- Creating a Skilled Workforce: partnering with educational institutions to promote specialized training programs in semiconductor technology will ensure a steady pipeline of talent to meet industry demands.

- Fostering International Collaboration: Building alliances with global semiconductor firms can facilitate knowledge transfer and attract foreign direct investment.

By taking decisive action in these areas, the Malaysian government can mitigate the current climate of uncertainty and reinstate confidence among chip manufacturers. By positioning the country as a leader in semiconductor manufacturing through strategic policy implementation,Malaysia can harness the potential of this vital sector,driving economic growth and technological advancement for years to come.