Trump’s Announcement on Apple: Implications for Domestic Manufacturing

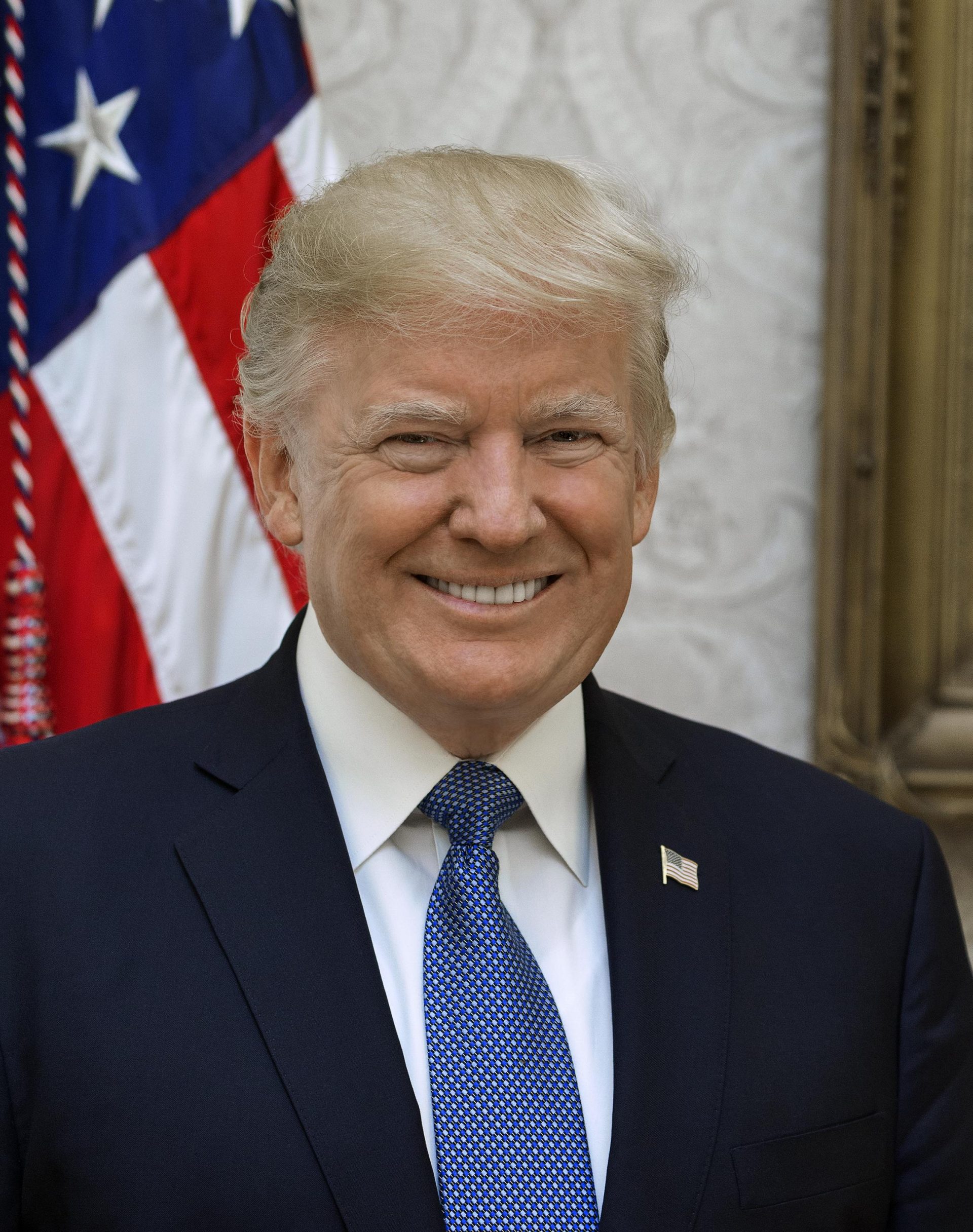

Donald Trump’s recent announcement regarding Apple’s potential shift towards domestic manufacturing has sparked a wave of speculation and debate within industry circles. while teh specifics of this transition remain vague, it raises significant questions about the future landscape of American manufacturing and the tech industry’s role within it. Given Apple’s longstanding reliance on overseas production, the idea of relocating operations to the U.S. could symbolize a monumental shift, impacting not only the company but also the entire sector.

The implications of this announcement are multifaceted:

- Job Creation: A move by Apple to increase manufacturing stateside could lead to the creation of thousands of jobs, providing a much-needed boost to local economies.

- Supply Chain Resilience: domestic production could enhance supply chain stability, reducing vulnerabilities exposed during global crises, such as the COVID-19 pandemic.

- Innovation and R&D: Establishing manufacturing hubs in the U.S. might stimulate further investment in research and development, fostering a more innovative surroundings.

- Political Ramifications: The announcement may influence upcoming elections, particularly in regions likely to benefit from new manufacturing jobs.

However, the success of such a strategy rests on various factors, including regulatory environments, labor costs, and the time required to ramp up domestic production capabilities. As stakeholders wait for more detailed plans and timelines from Apple,the broader implications for the U.S. economy and the technology sector remain to be fully realized.

Analyzing the Uncertainties Surrounding Apple’s Supply chain Shift

The announcement from former President Donald Trump regarding Apple’s potential shift of production to U.S. facilities has ignited widespread speculation.While Trump hinted at a significant transition in Apple’s supply chain strategy, the specifics remain vague. Analysts and industry experts are left to ponder the implications of such a move, considering several factors that could influence the feasibility and effectiveness of this transition:

- Cost Implications: Manufacturing in the U.S.typically incurs higher labor and operational costs compared to overseas operations. This raises questions about Apple’s pricing strategy and whether consumers would bear the brunt of these increased costs.

- Supply Chain Resilience: while domestic manufacturing could enhance supply chain resilience, particularly in times of global disruption, the immediacy of dramatically shifting a vast supply chain poses significant challenges.

- Workforce development: A shift to U.S. production would necessitate a skilled labor force, which may require investment in training and development to fill gaps in expertise.

- Regulatory Hurdles: Existing regulations and potential tariffs could complicate the process, impacting Apple’s ability to streamline operations as it seeks to adapt to a new manufacturing landscape.

In light of these uncertainties, the reaction from stakeholders across the tech industry is mixed.Some view the potential shift as a strategic move toward enhancing American manufacturing and creating jobs, advocating that this could strengthen Apple’s brand loyalty among U.S. consumers. Conversely, others remain skeptical, emphasizing that mere discussions will not suffice; actual implementation of such changes will require detailed planning and execution. As the situation unfolds, investors and consumers alike will be keenly observing how Apple navigates these complex decisions amidst evolving global manufacturing dynamics.

Economic Impact: What Apple’s potential Move Means for U.S. Jobs

The announcement regarding Apple’s potential shift to U.S. manufacturing raises significant questions about the economic landscape and job market within the country. Should Apple follow through on this initiative, it could herald a new era for american employment, particularly in the tech and manufacturing sectors. the implications of this shift are multifaceted, with positive ripple effects anticipated across various industries. Apple, being a leading player in technology, sets trends that often influence other corporations to reconsider their manufacturing strategies.In essence, the tech giant’s decision could prompt other companies to explore similar pathways, amplifying job creation in the United States.

In terms of employment, the impact could be ample, leading to the creation of thousands of local jobs.The potential for new positions would span numerous roles,including:

- manufacturing jobs: Direct employment opportunities in assembly and production facilities.

- Engineering positions: Increased demand for skilled engineers to oversee production processes.

- Logistics and supply chain roles: A rise in jobs to manage and streamline the flow of materials.

- Support staff: Growth in administrative and customer service roles to support the expanding workforce.

If Apple commits to substantial investment in U.S. production, the long-term vision could reshape the job market and bolster economic stability, especially in regions historically oriented toward manufacturing.

Recommendations for Policymakers to Foster a Thriving Tech Manufacturing Environment

To cultivate a robust tech manufacturing sector in the U.S., policymakers should prioritize establishing a comprehensive framework that addresses both the immediate and long-term challenges faced by the industry. This could include:

- Incentivizing Investment: Develop targeted tax credits and grants for companies that invest in domestic manufacturing and workforce development.

- Streamlining Regulations: Create a streamlined regulatory environment that facilitates quicker approvals for new tech manufacturing facilities while ensuring environmental standards are met.

- Enhancing R&D Funding: Increase federal funding for research and development in emerging technologies,fostering innovation and competitiveness.

Moreover, collaborating with private sectors is essential to ensure that workforce training aligns with industry needs. Initiatives can include:

- Public-Private Partnerships: Establish partnerships between educational institutions and tech firms to develop curricula that resonate with real-world skill requirements.

- Support for Apprenticeships: Promote apprenticeship programs that combine on-the-job training with formal education, helping to bridge the skills gap.

- Regional Development Zones: Designate tech manufacturing hubs with access to resources, infrastructure, and tax incentives to attract companies to invest locally.